Product

- Automatic-Reflow Line eries

- V-CUT & slop-edge equipment

- Drill and punch equipment

- Semiconductor packaging transfer molding press

- Automatic Machine

- FPCB&RPCB Exposing equipment

- FPCB&RPCB Visual inspection machine

- FPCB&RPCB Printing facilities

- FPCB&RPCB press machine

- FPCB&RPCB Wet process Surface Treatment Equipment

- Screen Film Loop inspection device

- process equipment for touch control products

- Developing device

- Welding Machine

- OTHER MACHINE

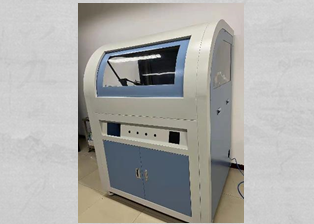

Automatic slice grinder DHY-555H

Automatic slice grinder

Other:

Features:

- Use acrylic sheet mold for inlay, with small grinding area and use of fixing glue, can be inlaid on both sides at the same time and the speed is fast.

- During fine grinding, only 20-50 μm of grinding allowance is left for the slices to save sandpaper loss.

- The effective use area of sandpaper is about 80-90%.

- It takes about 2 to 3 minutes to grind one slice on average, and 360 to 240 slices can be completed in 12 hours per shift.

- The grinding depth can be precisely controlled, which is conducive to fault grinding analysis.

- Grinding angle fixed control.

- The row holes can be ground at the same time after being calibrated.

- The grinding time of large and small holes is the same, and the success rate is more than 99%.

- The grinding depth can be precisely controlled, which is beneficial to fault grinding.