Product

- Automatic-Reflow Line eries

- V-CUT & slop-edge equipment

- Drill and punch equipment

- Semiconductor packaging transfer molding press

- Automatic Machine

- FPCB&RPCB Exposing equipment

- FPCB&RPCB Visual inspection machine

- FPCB&RPCB Printing facilities

- FPCB&RPCB press machine

- FPCB&RPCB Wet process Surface Treatment Equipment

- Screen Film Loop inspection device

- process equipment for touch control products

- Developing device

- Welding Machine

- OTHER MACHINE

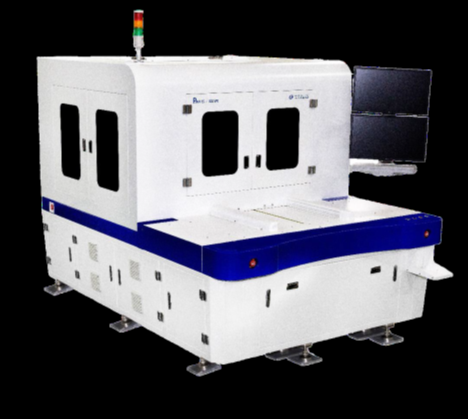

Automated Optical Inspection System

Automated Optical Inspection System

MODEL:PAVIS-30LV

Other:

USE:

PAVIS-30LV is the best solution for automatic Via Hole inspection after laser drilling and Desmera processing.

The biggest difference between this equipment and traditional inspection equipment is that it uses a color camera, which can inspect the defects of different colors at the bottom of the hole.

Features:

- In order to improve the defect discrimination ability, use color optical system, super high resolution, improve inspection ability.

- Real Time Auto Focusing, using a specular reflective sensor, after Real Time measures the distance between the camera and the product, Synchronized with the Motion Z axis for accurate corrections. (possess domestic and foreign patents)

- Adopt porous ceramic table, uniform adsorption force, electric insulation effect, prevent adsorption traces.

- Analyze testing and inspection data, provide engineering capability evaluation tool and Spec Out position confirmation function.

- Apply AI solution by confirming defect only by VMS image.

- Sufficient data storage space, which can be stored for at least one year.

7. Using the ODB Data editing system, inspection recipes can be quickly generated.