Product

- Automatic-Reflow Line eries

- V-CUT & slop-edge equipment

- Drill and punch equipment

- Semiconductor packaging transfer molding press

- Automatic Machine

- FPCB&RPCB Exposing equipment

- FPCB&RPCB Visual inspection machine

- FPCB&RPCB Printing facilities

- FPCB&RPCB press machine

- FPCB&RPCB Wet process Surface Treatment Equipment

- Screen Film Loop inspection device

- process equipment for touch control products

- Developing device

- Welding Machine

- OTHER MACHINE

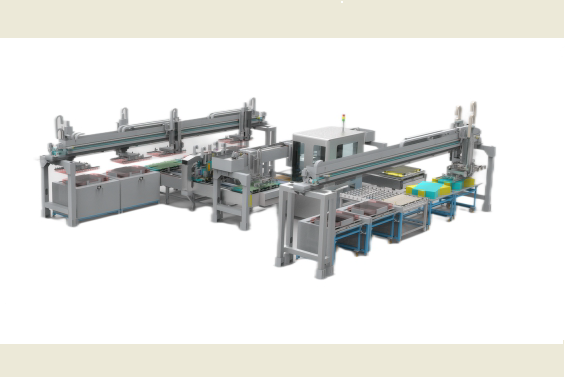

PP Core Plate Automatic Riveting System

PP Core Plate Automatic Riveting System

Other:

Characteristics

Efficiency:Capable of efficiently completing pre-stacking,enhancing production efficiency

Speed and Efficiency:Automated pre-stacking equipment can rapidly

complete pre-stacking,significantly reducing the PCB production cycle

and enhancing overall efficiency

Flexibility:The PCB automatic pre-stacking system can be flexibly

configured according to various product stacking requirements and

accommodate different size changes

High-Precision Stacking:Visual calibration for pre-stacking ensures

precise alignment

Data Management:The automatic pre-stacking system can connect

with production management ERP,MES systems,enabling real-time

monitoring and recording of production data for convenient subsequent

data analysis,quality tracking,and statistics

|

Product Specifications |

|||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||